The new German Supply Chain Act – Webinar with prewave

(In German)

Many suppliers, various products and no predefined processes for social and ecological evaluation in your supply chain?

The new German Supply Chain Act presents many companies with new challenges and requires companies purchasing to develop new skills and processes. Digital solutions are essential to help reduce complexity and to evaluate large amount of data efficiently and purposefully.

Speaker: Harald Nitschinger (CEO – prewave) and Klaus Wiesen (CEO – sustainabill)

In this Webinar you will learn:

How the AI-based screening of publicly available information and collaboration in a cloud software is helping to fulfil the requirements of the Supply Chain Act.

Why companies should now set up a holistic risk management system in order to be able to efficiently implement future sustainability requirements in their supply chain.

How an efficient, risk-based approach can be efficiently implemented and how it is ensured that the focus is placed on the relevant supply chains.

Riskmanagement in supply chains of mineral resources

(In German)

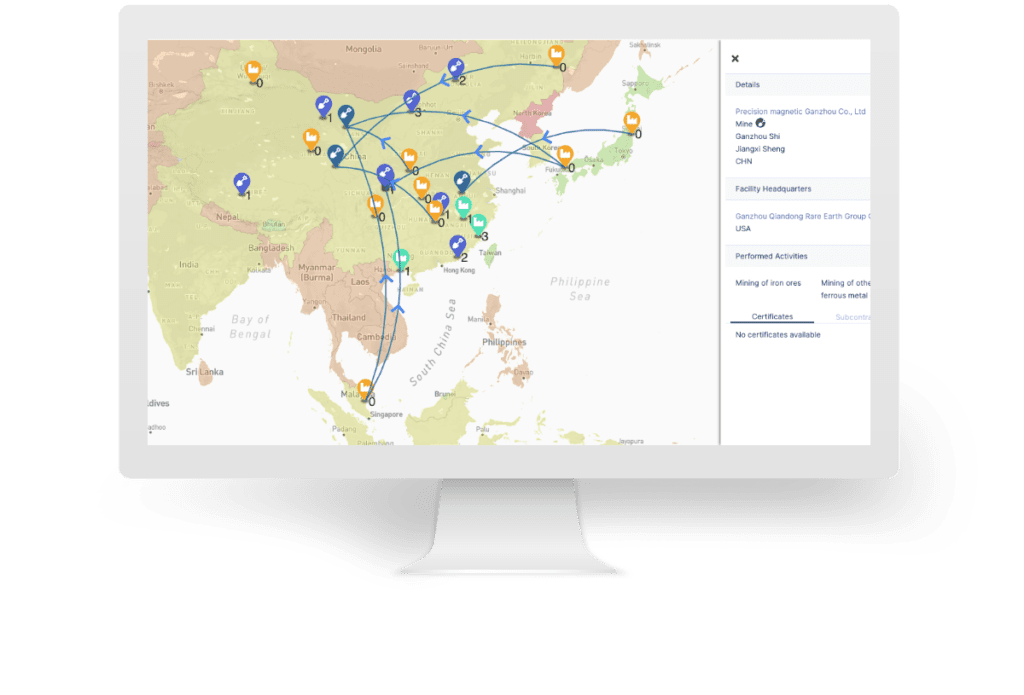

The requirements for transparency in mineral raw material supply chains are increasing. In addition to conflict minerals (3TGS), more and more raw materials are becoming relevant, especially in the field of future technologies.

It is now important for companies to integrate a holistic and future-proof management system for sustainability into their procurement processes. Whoever approaches this now will realize competitive advantages and ensure future success.

Speaker: Carolin Friedrich (Stakeholder Reporting), Isabel Urrutia (Projekt-Consult) und Miriam Gogel (sustainabill)

In this Webinar you will learn:

What transparency requirements do stakeholders have along the supply chain?

How do digital solutions help to reduce complexity and systematically collect data.

How do I prepare a due diligence report.

Emission-free supply chains – through digitalization and transparency

(In German)

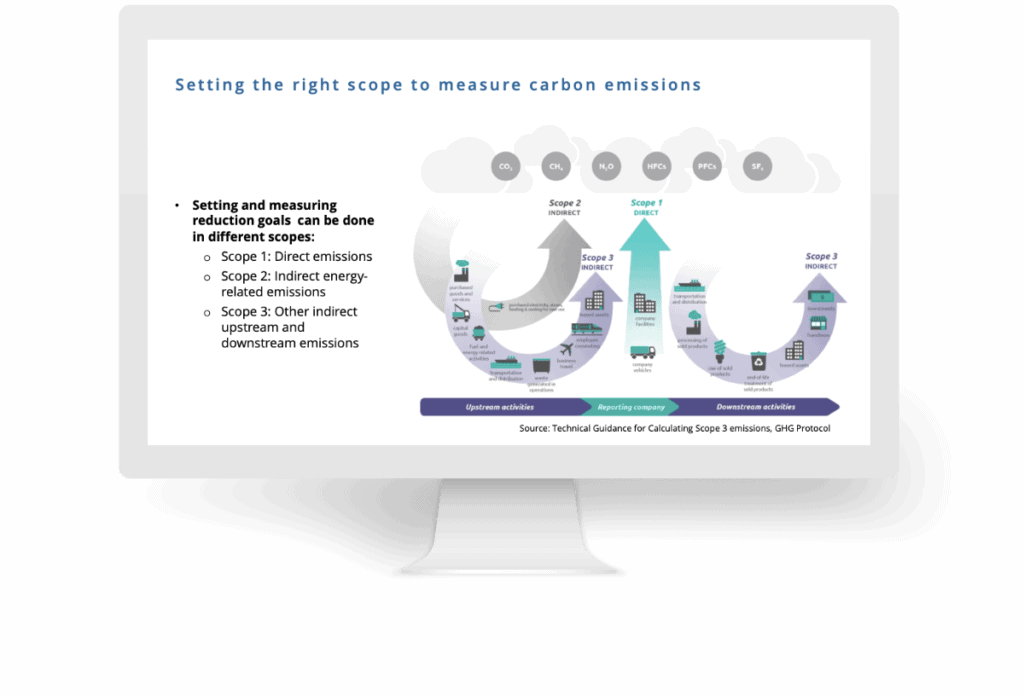

Around 75% of greenhouse gas emissions of companies are generated in the supply chain. This makes the supply chain a particularly relevant lever for climate protection measures. Legislators and investors are increasingly demanding transparency and verifiable measures from companies with regard to climate protection in the supply chain.

Speaker: Klaus Wiesen, CEO sustainabill

In this Webinar you will learn:

What data is needed to identify emissions hotspots?

How to meet requirements for international standards and reporting audits.

How to successfully engage suppliers in data collection.

How to implement the German Due Diligence Law

(In German)

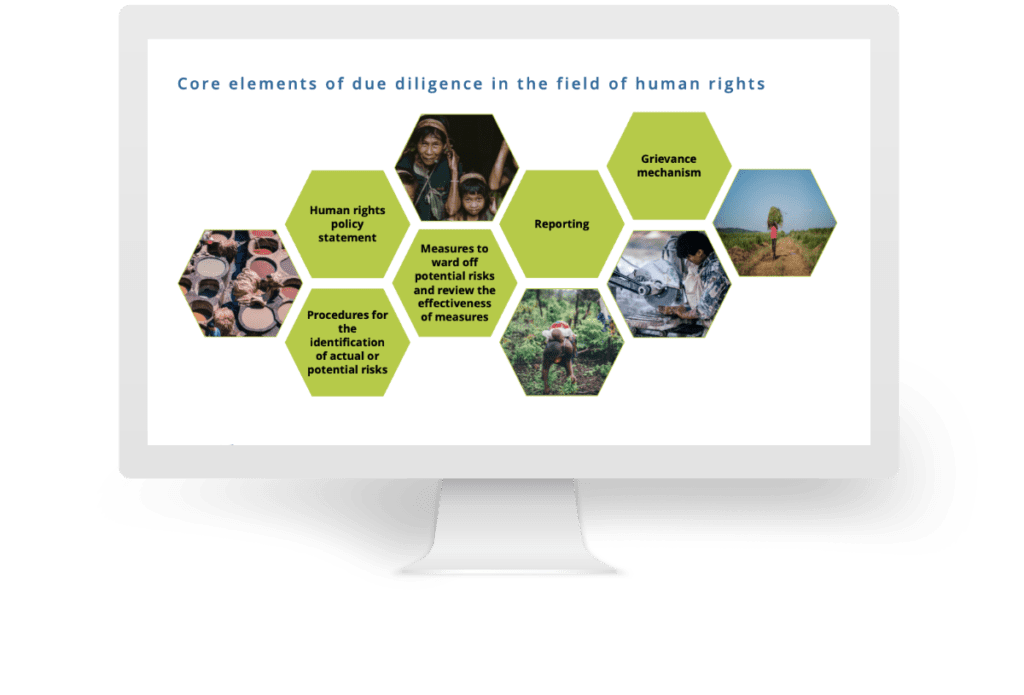

In this webinar you will learn how a successful and future-proof implementation of the German Due Dilligence Law can be achieved. Together with our partner Löning –Human Rights and Responsible Business, we discuss practical and innovative solutions.

Speaker: Alice Homuth, Markus Löning, Klaus Wiesen

In this Webinar you will learn:

What the Due Dilligence Law means and how to implement it efficiently in your company

How the integration of legal requirements into your management systems and functions works

Best practice implementation examples from companies

How to monitor your scope 3 climate targets

You have set climate targets. Now, what's important when you want monitor these targets?

Panelist: Miriam Gogel, Head of Sales and Customer Relationships

Choosing the right information for target monitoring

Efficiently monitoring data and communicating requirements to suppliers

Engaging with your suppliers to ensure progress on your targets

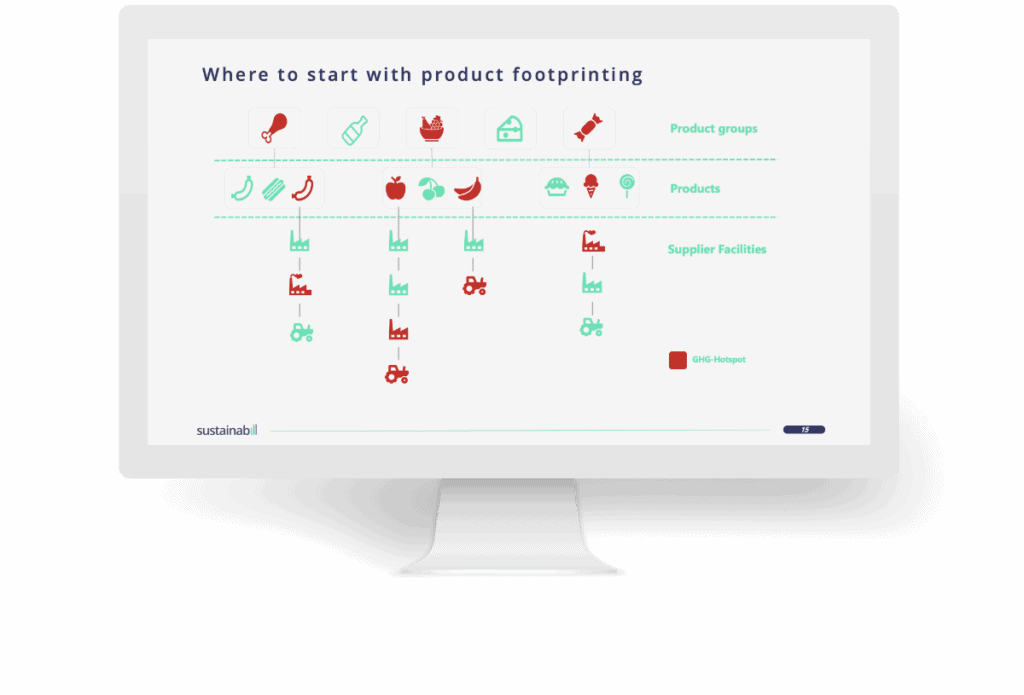

How to measure the footprint of your sourced products

This webinar explains how to focus on the right supply chains to achieve the largest impact.

Panelist: Klaus Wiesen, CEO sustainabill & Miriam Gogel, Head of Sales and Customer Relationships

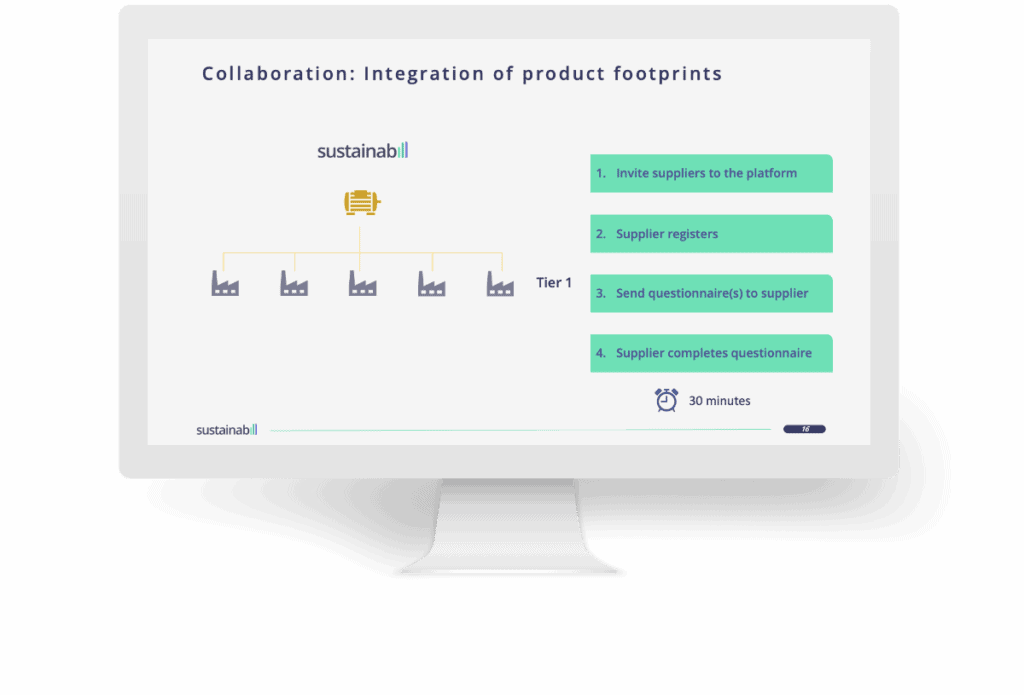

What information is you needed to calculate and monitor the footprint of your products.

How sustainabill’s processes and features are designed to ensure efficient and targeted data collection for product carbon footprints.

How we enable supply-chain-specific monitoring and improvement processes.

Climate action through collaboration

This webinar explains why climate action requires new forms of collaboration.

Panelist: Klaus Wiesen, CEO sustainabill & Miriam Gogel, Head of Sales and Customer Relationships

How to increase transparency through engaging with your suppliers and/or customers.

How our full-service approach supports collaboration between buyers and suppliers.

How our platform ensures benefits for everyone within the supply chain.

Climate Emissions – Collecting Fact-Based Data from your Supply Chain

This webinar elaborates how to use supply chain mapping to enable a fact-based cradle-to-gate assessment of carbon emissions.

Panelist: Klaus Wiesen, CEO sustainabill

The benefits of supply chain mapping for pro-active sustainability and risk management

Data requirements for a fact-based assessment of carbon emissions

How to use supply chain mapping to identify hotspots and monitor your emissions

Supply Chain Mapping – How to Trace a Product to the Source

This webinar shows buyer and supplier perspectives of the sustainabill platform and how products can be traced to the source while being 100% GDPR compliant.

Panelists: Klaus Wiesen, CEO sustainabill & Dr. Thorsten Merten, CTO sustainabill

The benefits of supply chain mapping for pro-active sustainability and risk management

Important steps to consider for supply chain mapping and how to use the sustainabill cloud to map the supply chain step by step

How to integrate supply chain mapping in your operations

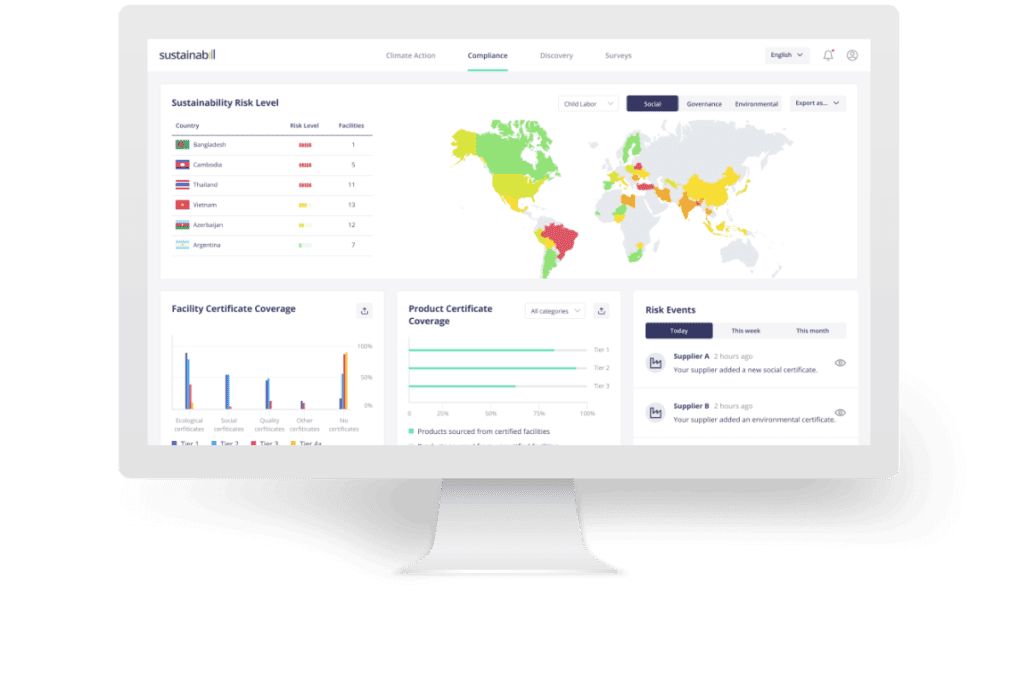

Human Rights – Monitoring Social Compliance of the Entire Supply Chain

Ensuring human rights is an important driver to identify the actors upstream the entire supply chain. This webinar gives an introduction to social compliance and shows how the sustainabill cloud plattform can help you identify and manage human rights issues.

Panelist: Klaus Wiesen, CEO sustainabill

Current and future legal requirements in regard to human rights and social compliance

The benefits of using secondary materials

How to use the sustainabill cloud platform to monitor social compliance

Circular Economy – How to Identify the Proportion of Secondary Materials Used in Your Products

While many circular economy strategies focus on how to reuse and recycle the product, an important question which must be answered first is, how much recycling material you are already using in your product.

Panelist: Klaus Wiesen, CEO sustainabill

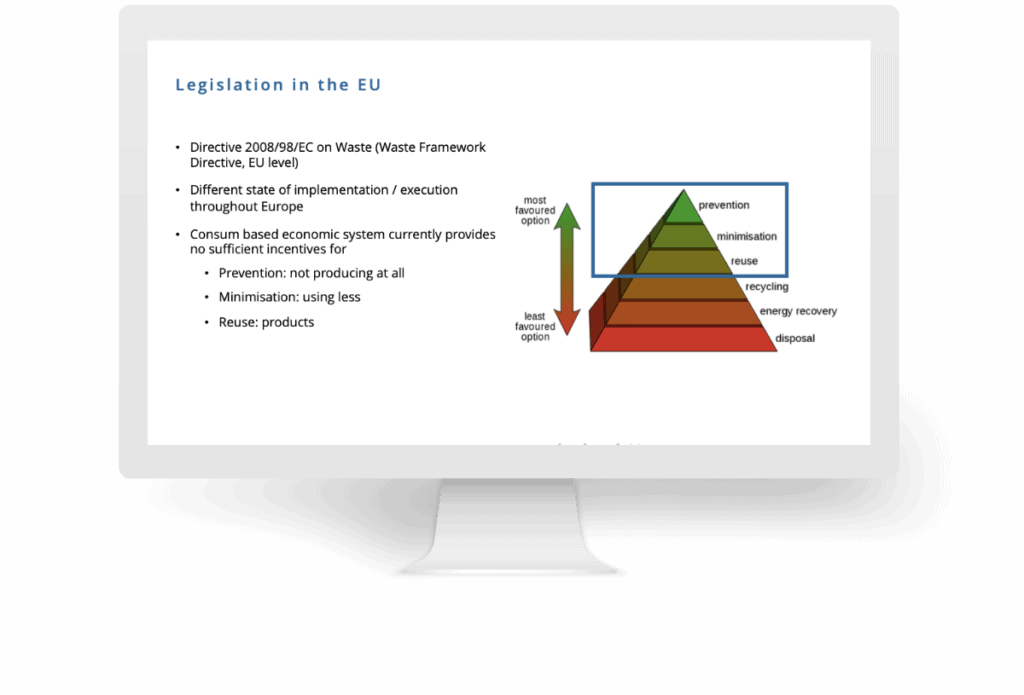

Overview of circular economy strategies applicable for your company

The benefits of using secondary materials

How to use supply chain mapping to identify secondary materials and to collaborate with sub-suppliers to increase the share of secondary materials in your supply chain